|

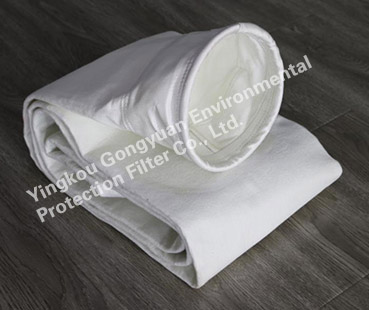

Normal temperature needle felt filter bag |

||

|

Fabric organization |

Polyester fiber + polyester base fabric |

|

|

Gram (g/m2) |

500-600 |

|

|

Thickness(mm) |

1.8-2.0 |

|

|

Breaking strength(N/50mm) |

Warp |

≥1000 |

|

Weft |

≥1300 |

|

|

Elongation at break(%) |

Warp |

≤35 |

|

Weft |

≤55 |

|

|

Breathability(dm3/m2/s) |

30-50 |

|

|

Recommended temperature (℃) |

Continuous use |

80-130 |

|

Instantaneous high temperature |

150 |

|

|

Recommended wind speed (m/min) |

0.6-0.8 |

|

|

Post processing |

PTFE Impregnation、Heat setting、PTFE Laminating |

|

|

Emission concentration mg/m3 |

≤20 |

|