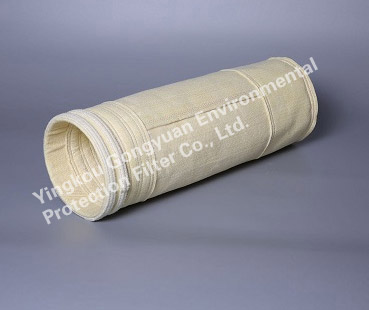

The glass fiber composite needle felt filter bag combines the advantages of glass fiber + chemical fiber to overcome the shortcomings of a single material, and makes a new composite filter material with high performance and high cost performance. When the filter material is cleaned, the jitter is good, the dust is easy to peel off; the porosity is high, the gas permeability is good, the dust collection efficiency is high, and the service life is long; the high-strength and low-stretch industrial yarn is used as the base cloth to greatly increase the strength; the PTFE microporous film is used. The pore size is reduced, the porosity is high, the filtration precision is high; the superior glass fiber + chemical fiber is selected, the acid and alkali resistance, hydrolysis resistance and wear resistance of the filter material are all enhanced; the filter material is post-treated by PTFE impregnation, and the treatment is improved. Waterproof and oil proof; suitable for wide working conditions, low energy consumption and low maintenance cost;

Main technical parameters of filter bag

|

High temperature composite needle felt coated filter bag |

||

|

Fabric organization |

Microfiber + short fiber |

|

|

Gram (g/m2) |

950-1000 |

|

|

thickness(mm) |

2.0-2.2 |

|

|

Breaking strength (N/50mm) |

Warp |

≥1300 |

|

Weft |

≥1200 |

|

|

Elongation at break(%) |

Warp |

≤10 |

|

Weft |

≤10 |

|

|

Breathability(dm3/m2/s) |

80-150 |

|

|

Recommended temperature (℃) |

Continuous use |

200-260 |

|

Instantaneous high temperature |

≤280 |

|

|

Recommended wind speed (m/min) |

0.6 |

|

|

Post processing |

PTFE Impregnation、Heat setting、PTFE Laminating |

|

|

Emission concentration mg/m3 |

≤20 |

|